Harse Family Of Oxford

The Harse Families In Oxford - Cricket Balls and Bicycles

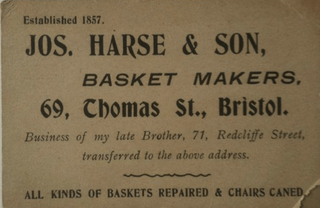

Benjamin Harse, Bristol Shoemaker, brought his family to Oxford around 1861. The following extracts provide some insight into the family and their life.

Primrose Hill Cricket Club- known locally as the 'Hillites' - were formed in 1875, and were very much a 'village' club in their infancy. Their early years were littered with interesting and amusing goings-on.

In 1891 they won the Lumb Cup and opened a 'champagne account' at a local inn to celebrate. In the same year the club allowed two of its members - George Beaumont and J.A. Kennedy - to 'hawk tripe and fish in the cricket field on payment of sixpence at each match'; it also informed the police that gambling was taking place in the adjacent football field (but unfortunately, the Chief Constable didn't seem very interested in the matter).

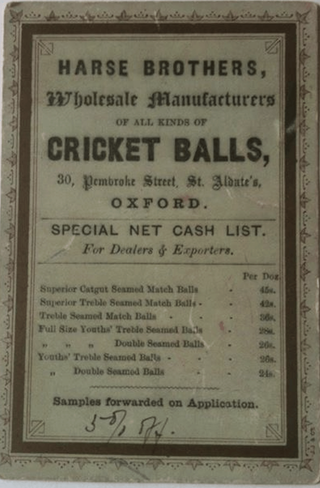

In 1893 the club employed Fred Dawson, of Lockwood, as professional at a rate of 10/6d per week, with the promise of a benefit, 'provided he is willing to attend practice three nights a week'. Three years later, on 1 April 1896, the authorities 'resolved we order one dozen best match balls from B. Harse (Oxford) at 50/- per dozen, less 12 and a half per cent for ready money and that we ask J. Kennedy to lend us the money.'

THE LONDON GAZETTE, AUGUST 6, 1909.

NOTICE is hereby given, that the partnership lately

subsisting between us the undersigned, Morton

Philip Harse and Alfred Colin Harse, carrying on business

as Cricket Ball Manufacturers, Cycle Agents, and

Athletic Outfitters, at No. 26A, St. Giles-street, and

Number 39, Pembroke-street, Saint Aldates, in the city

of Oxford, under the style or firm of "HARSE

BROTHERS," was, as from the 27th day of March, 1909,

dissolved by mutual consent. All debts due to or owing

by the said late firm will be received and paid by the

said Alfred Colin Harse, who will continue the said

business under the present style or 6rm of " Harse

Brothers."—As witness our hands this 29th day of July,

one thousand nine hundred and nine.

MORTON PHILIP HARSE.

ci« ALFRED COLIN HARSE.

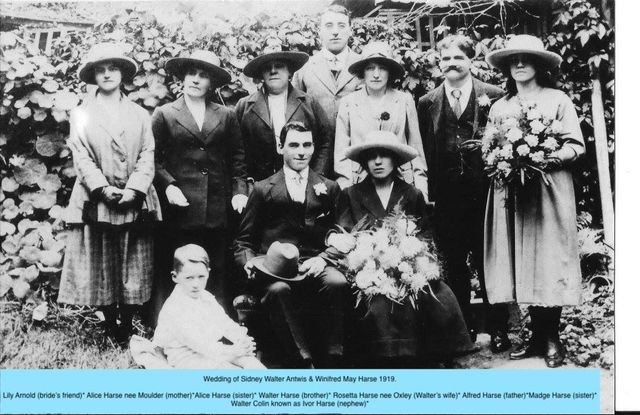

The Exons of Stogursey

On Christmas Day in 1873, Charles Exon married Sarah Ann Harse in Oxford. Her father, Benjamin Harse, had been a shoemaker in Bristol but for unknown reasons had moved to Oxford where he and his sons set up in a much more unusual leather business, cricket ball manufacturing. Although Charles and Sarah Ann carried on the bakery in Bristol for some time, they eventually moved to Oxford where the family baking business continued at 35 Little Clarendon St, St Giles in the heart of Oxford. Their bread was supplied to the nearby college, Trinity. The last Exon baker was Douglas Exon, one of Charles’ grandsons, who had a business at Dorchester-on-Thames until the 1970s.

A History of Socialism in Oxford, St Clements

There had been a radical culture, working class struggle, running through Oxford from the early nineteenth century. In the 1880’s there was as a whole, a growing interest of ‘Socialist’ ideas. The foundation of the Socialist League in London by William Morris had repercussions in St Clements. A group of Socialists had regular meetings in the ‘Druids Head’ pub on George Street until the landlord who was a Liberal, objected to the Socialists and expelled them from the pub. This group then went to meet on the Cowley Road in the ‘Elm Tree Tavern’. It was from here that the Oxford Socialist League was born. The formation of the Oxford Socialist League was motivated by Charles Faulkener, a mathematics lecturer at University College, who was also a friend of William Morris.

A document, known as the Foundation document of the Oxford Socialist League, prepared and sent to the Executive Committee of the Socialist League in London requesting affiliation to the national body. The group signed the letter of application on 9th March 1885. The names of those at the meeting included:

George Harse, St Mary’s Road

Walter Harse, St Mary’s Road

Morton Philip Harse, St Mary’s Road

Alfred Cohn Harse, Hurst Street

Several of the group lived in St Clements, or East Ward, as it is known today.

However the Oxford Socialist League did have a problem in attracting new members. The failure to gain working class support led to its decline. There is no evidence to suggest that the Oxford Socialist League was ever involved in trade union disputes and it was perhaps this that led to its collapse. Therefore the Oxford Socialist League did not interest working class people, thus it became a mere talking shop for intellectuals with Socialist ideas. The lack of support thus eventually led the Oxford Socialist League to fade away. While an early pioneer of the labour movement in Oxford, and the Labour Party, the birth of the Trades Council in Oxford filled the vacuum in the working class movement.

Extract from Quilt Winders and Pod Shavers by Hugh Barty-King

Edward Martin had a cricket ball works at Teston in Kent. When he died in 1869 he bequeathed the Martin cricket ball works and its goodwill to the three or four craftsmen who worked for him and Alfred Reader, in equal shares.

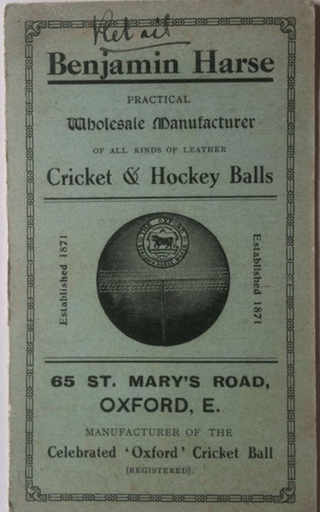

Alfred Reader knew nothing about cricket balls and left the others to run the business. Without a traveller to solicit orders from clubs the business declined and was soon in debt. Alfred bought out the partners in 1871 and cleared the debts. In the same year, back at the University town which Edward Martin had left ( Fuller, Pilch and Martin, Christchurch Ground, Oxford). Benjamin Harse, sole maker of the noted “Oxford” ball, as he was to style himself, set up at 81 St Mary’s Road. In 1873 Alfred introduced the “Reader ball” which was an alternative to the “Duke” and “Twort”. In 1888 Alfred Reader employed six craftsmen making a range of fifteen qualities ranging from 36 dozen “B” match halls at 36 shillings a dozen to Youths at 5 shillings a dozen.

A notebook in 1895 indicates that Reader’s customers included Martin’s competitors the Harse brothers. The Oxford firm had been weak on the promotional side and it seemed they had failed to get their name across even after sixteen years. Benjamin Harse according to his business cards, offered “the most RELIABLE and CHEAPEST MATCH and CATGUT-SEWN BALLS in the trade Of course Harse brothers were saddled with an unfortunate name from the point of view of promotion if they had to rely upon too many salesmen with the inability to aspirate. Meanwhile Alfred Reader continued to make rapid progress building a company that was to last sixty-three years.

Comments by Norman Harse in the Oxford Mail in 1971

His father, George, had told him that the family originated in the West Country.

The words ‘Benjamin Harse, Cricket Ball Manufacturer’ could be seen on the side of a tall building at 87 St Mary’s Road, Oxford up until the sites redevelopment in the 1980’s. That is where the first member of the Harse family to make cricket balls in Oxford set up in business in 1871.

Norman Harse made cricket balls in the New Inn Yard, St Aldates until 1951. .When Uncle Ben was first apprenticed to Johnny Best in the Cowley Road Oxford was the centre of the Cricket Ball making industry. What is more it was a booming industry so it shouldn’t have been any skin off Johnny’s nose when Uncle Ben set up in business on his own in St Mary’s Road. However Johnny was upset and he was even more upset when Ben took his three younger brothers Cohn Morton and Walter, into business with him. Perhaps Jonny anticipated that Ben would be no more successful at keeping his young apprentices than he was. If he did he was right because before long Cohn, Morton and Walter fell out with Ben and set up in business on their own as Harse Brothers.

At this time, about the turn of the century, there were five cricket ball making firms in Oxford all doing good business. But it would seem that the Harse brothers were adventurers ready to turn their hands to any enterprise which might bring in a bit of money. In addition to cricket ball making workshops in Magdalen Road and Pembroke Street, they had cycle shops to meet growing student demands in St Giles and St Aldates and ran an extremely profitable bookmaking business from behind the cover of these activities. To give an idea of the scale on which they worked Norman received a cheque in the late 1960’s for an outstanding debt of 100 Guineas from someone who presumably had a conscience on his deathbed.

If they all stuck with their trade there is an outside chance that Oxford would remain the centre of the cricket ball making industry still (in 1971). However cricket ball makers made it a rule never to work on Mondays. They were a boozy lot. Sometimes it took them three days to recover one of their more strenuous jags.

By the time the First World War had ended Tonbridge, Kent had taken over from Oxford. There was still money to be made out of cricket balls. George, the youngest of the five Harse brothers, took over the equipment and set up in business with his eldest son, who was also named George aka Harold. They had their workshop in what was then Donnington Road (now Silver Road) next door to the old Donnington Arms, and prospered until the outbreak of the Second World War. By the time the war ended George Snr had died.

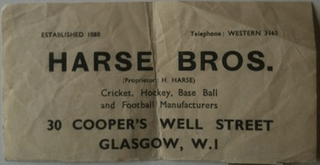

When Harold returned to Oxford after the war he set up in business with Norman under the old name of Harse Brothers at the rear of New Inn Yard, St Aldates, then when Norman was established went to Glasgow and opened a second branch ‘of the business until ill health forced his retirement.

For a year or two Norman did all right. Then the weather and the Indian cricket ball industry began to take its toll. Harse Brothers had regular orders from the colleges who they were allowed to supply direct. They didn’t rely upon them for their bread and buffer, nor on the County Cricket Clubs. Their main source of income was the smaller cricket clubs.

There were about 36 000 of these little clubs up and down the country each playing on average one match each weekend during the summer. Generally they would use two new balls per match, one for each innings. At the time halls cost less than 10 shillings (fifty pence new money in 1971) each. If you get a wet Saturday that’s 72,000 cricket balls not used. You get a wet summer and even the strongest cricket ball maker is in trouble. Then a lot of clubs changed to cricket balls made in India which the clubs decided were good enough for their purposes and the writing was on the wall. The trade died a lingering death in Oxford. In 1951 Norman sold all the equipment to become a partner in an Oxford taxi business. The only souvenier retained was a lighter made in the shape of a cricket ball several of which he made himself, along with hockey halls in an attempt to diversify.

Robert Levens. Emeritus Fellow of Merton College recalled the following in the Oxford Mail in 1971.

I came to know George Harold Harse, who joined his father in the cricket ball business, when I lodged at his house in Divinity Road in my final year as an undergraduate (1922/3). He had been one of the lads of the village a decade earlier and had many tales to tell of the gilded youth who spent their time and money in the George Bar.

The Harses were splendid company, once one learned not to be embarrassed by their neglect of the aspirate, and they celebrated the end of my final examinations by including me in a family party which travelled to Ascot in a 14 seat charabanc, a formidable precursor of the minibus This was my first race meeting but it was also my first all-day alcoholic excursion, and I cannot recall actually sighting any horses.

I am sure that no cricketer of the time would deny that the Harses and others of those days knew how to make cricket balls, not the sort of stuff you see umpires having to replace nowadays because they have been knocked out of shape

Alice Abbott recalled the following in the Oxford Mail in 1971.

In I914 I was living at 128 Magdalen Road and Mr Harse and family were our next door neighbours. Mr Harse had a workshop in his back garden of 127 Magdalen Road in which he made cricket balls

Extract from article supplied by George Harold Harse to an America newspaper in the 1950’s.

The Harse family has manufactured cricket balls by hand for three generations. This tradition is being continued by myself, as head of the firm of Harse Brothers, Coopers Well Street, Glasgow, Scotland. My father and grandfather had there headquarters in Oxford, England, but I came North to gain additional experience in the factory of William Tomlinson Ltd., Glasgow, manufacturers of footballs, rugby, cricket and hockey balls.

The business is now long standing and provides a ready supply of balls to customers both in Scotland and abroad. There is not an item of machinery in the Coopers Well Street premises. Machine made balls are not bad but they are not the real thing. No top class cricketer would use one. Consequently there is always a demand for my products. Indeed, without any great effort I could probably multiply many times over the number of orders we receive That would involve expansion beyond my plans and result in a re-organisation that would reduce the work to ordinary “factory production”.

Every ball today is handled at some stage in its making by me and I can take ‘over at any point from one of the team of craftsmen and women. My only real problem lies in the fact that England is the traditional home of cricket. Consequently, most Scottish firms place their orders “south of the border”, ignoring the fact that they can obtain balls on their doorstep, produced by Scottish craftsmen.

As a result we have the curious situation that most of our orders come from England.

In 1953 there was a great deal of concern among sports gear manufacturers due to the threat of competition from Indian firms. I had some of the Indian balls sent to me and, upon examination, decided there was no real threat. The Indian balls were little more than toys in comparison with ours. Even their better ones were badly misshaped. Their lower price diverted them to markets I did not touch. Indeed I have difficulty in selling even our own medium quality ball. Only the best balls earn regular demand.

The production of cricket balls in the time honoured fashion is an absorbing process. The raw materials in the storerooms in the Coopers Well Street premises are bales of heavy hides, balls of hemp and worsted and heaps of cork. On a core of little more than a cubic inch of cork is wound yard upon yard of worsted thread alternating with layers of cork in strip form. To the uninitiated the process seems simple until an attempt is made to follow the motions of the craftsmen engaged upon the task. While his body moves in a steady rhythm, his fingers tipped with leather protectors, are a blur of speed. For the worsted, dampened to give it elasticity is not only wound over the cork, but each turn is also “netted” so that there can be no slipping or movement in the layers as the thread dries and shrinks.

The regularity of the sphere is a miracle in itself and requires only occasional shaping, a few taps with a concave shaped hammer as it lies in a cup shaped mould. As it nears completion, the sphere is repeatedly weighed alongside the leather covering later to be attached to it and a knob of deer grease afterwards to be worked into the leather, for exact weight to a fraction of an ounce is vital. The finished product weighs 51/2 ounces.

Preparation of the covering calls on the skill of further craftsmen. The hides, after washing and cutting, are passed to the next man, four segments of leather to each ball. The craftsmen, with neat stitch that would be the envy of the finest seamstress, unites these pieces in pairs. The resulting hemispheres appear to be cut from the same piece of leather and from the outside, there is no sign of the tough hemp thread used to join the sections. Women take over the subsequent operation, forcing the halves of the covers over the core with special clamps and stitching them in position.

In this operation every stitch counts as much for the sake of appearance as for strength. It is easy for a machine to achieve perfect uniformity, but skill of the highest order is required for human hands. Not only skill is involved The task demands unlimited patience. For a needle, a hog’s bristle is used. These come from Korea and are scarce and extremely costly. The final stage in production is the application of the firm’s name and “Oxford” trademark in gold leaf and a coating of the balls with a fine varnish.

In addition to cricket balls we also make footballs (I have taken out a patent for the special valve attached to the bladder) and hockey balls. As to plastic covered balls they could be the only possible answer to the problems of dampness. There are people who are convinced that certain types of leather are genuinely waterproof. But they are not. I have tried them.

Certainly if you tie a piece of top quality chrome leather up by its four corners to make a bag shaped container it will hold water for years if left that way. But it needs only a scratch on the surface of the leather for the water to seep through. Consequently, on the playing field, only plastic covered balls can alone achieve perfection of waterproofing.

Comments by Marjorie Fox daughter of Percy Harse

Recalled visits to Oxford with her sister to visit grandparents George and Lavinia Harse

Remembered Doris and Phyllis who used to visit their home in the country together with Yvonne.

George Harold visited them at Bexhill on Sea as he had a girlfriend there and always visited on a Sunday for card games with Ted (husband to be). This was before the war. During the war Marjorie worked at the Admiralty and would always check for Cyril’s safety in HMS Suss.

Comments from Joan Hall ex wife of Percy Harse

My first husband Percy was descended from Henry Harse 1809 and Emily brother of Benjamin Harse.

Thinks it is a family trait to be uncommunicative so much so that Arthur Victor 1896 shoemaker, moved to Scarborough and changed his name to Harris. He would never have been traced but for his granddaughter. He refused to talk about the family. He died in 1998 aged 99 years.

Comments from Walter C.T. Harse son of Walter Colin Harse

Walter rang a Peter Harse who lived in the Midlands. Unfortunately he was unwilling to provide any information. This seems to be a family trait. One of the Harse family ran a pub by the river at Kingston Bagpuize. Walter’s mother was a barmaid at The Grapes pub, presumably in George Street, Oxford.

See Harse, Ivor - An Oxford Childhood page

GENERATIONS OF THE HARSE FAMILY

1. Benjamin Harse (1822-1890), Son of John and Sarah Singleton

Married Ann Adams

The 1861 Census describes Benjamin as a Shoe Maker living at 10 Marston Road. Ann is described as a Shoe Binder

The 1871 Census describes Benjamin as a Boot Maker living at 52 Pembroke Street (now Rectory Road), off Cowley Road. Son Benjamin was an unmarried Cricket Ball Maker, Sarah and Clara were Dressmakers and Walter was an unemployed Errand Boy. The five younger children were still at school.

The 1881 Census describes Benjamin as a Master Shoe Maker. He and Ann were still living at 52 Pembroke Street with four sons and a domestic servant Matilda Welford. Benjamin was described as a Master Cricket Ball Maker while Cohn Morton and George were Cricket Ball Makers.

2/1. Benjamin Harse (1848-?), Son of Benjamin and Ann Adams

The 1883 Walters Directory has Benjamin making cricket balls at 65 St Mary’s Road.

The 1895-6 Walters Directory has Benjamin living at 65 St Mary’s Road while Kelly’s Directory has him at that address in 1926

2/2. Walter John Harse (1856-?). Son of Benjamin and Ann Adams

Married Elizabeth Barnes (1858-?)

The 1883 Kelly’s Directory has Walter living at the Sherbourne Arms, 1 Castle Street where in 1881 William was the Licensed Victualler.

The 1891 Census describes Walter as a Cricket Bat Maker living at 9 Speedwell Street. Elizabeth is described as a Lodging House Keeper and Head of the Household.

The 1895-6 Walters Directory has Walter as a Cycle Agent (Harse Brothers at 2 Pembroke Street and living at 96 St Aldates. However the 1900 Kelly’s Trade Directory has him trading as a Cricket Outfitters at 96 St Aldates.

The 1905 Kelly’s Directory has Morton living at 114 Abingdon Road. Harse Bros were identified as Cycle Agents at 26a St Giles.

2/3. Wilfred George Harse (1860-?), Son of Benjamin and Ann Adams

Wilfred married Elizabeth Stringer from Marston, Oxford. According to the 1891 Census he was married to a Polly from Watford.

The 1881 Census describes Wilfred as a Licensed Victualler living at the Sherbourne Arms, 1 Castle Street with his wife Elizabeth and daughter Alice (8 months), mother in law Martha Stringer (age 65) and a Servant Laura Cooper.

The 1891 Census describes Wilfred as a Cricket Ball Maker living at 4 Bear Lane with his wife Polly and son Wilfred aged 3 years, brother George and another Cricket Bat Maker Thomas East.

2/4. Alfred Colin Harse (1861-1939), Son of Benjamin and Ann Adams

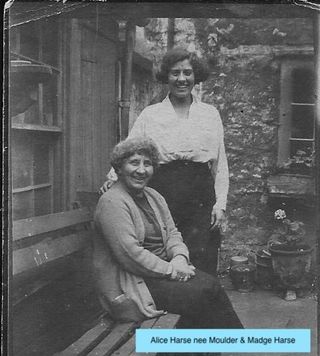

Alfred married Alice Moulder from Oxford. The 1883 Kelly's Directory had her father at the Refreshment House, 63 George Street.

The 1891 Census describes Alfred as a Cricket Ball Manufacturer living at 30 Pembroke Street with his wife Alice and two children Alice (10) and Walter (6 months). It may be that Alice F died prior to Alice V being born in 1896.

In 1895 Walters Directory Alfred is living at 17 London Place According to the 1899 Directory he had moved to Wellington Villa, Little Clarendon Street. In 1905 Kelly’s Directory Alfred is described as a Cycle Agent at 30 Walton Street as well as living at Wellington Villa.

In 1928 Kelly’s Directory Alfred is described as a Cycle Agent at 27 St Giles. By the year of his death in 1939 the address had changed to 26a St Giles. Daughter Madge was the Cycle Agent in 1945

Madge married her Cousin Benjamin, son of Morton Philip Harse.

2/5. Morton Philip Harse (1864-?), Son of Benjamin and Ann Adams

Morton married Alexandra from Doulting, Somerset.

The 1891 Census describes Morton as a Cricket Ball Manufacturer living at 24 Pembroke Street with his wife Alexandra and three children Mabel (6), (1 month) and domestic servant Eliza Edwards Morton (2), Philip.

The 1895-6 Walters Directory has Morton living at 57 Southfield Road. The 1905 Kelly’s Directory has Morton living at both 50 Beechcroft Road and 39 Pembroke Street. In 1915 he was living at 114 Abingdon Road where Walter was living in 1905. By 1921 Morton had moved to 158 Walton Street. Morton was living there until at least 1943 as Alexandra is listed at that address until at least 1962.

Son Philip was killed at the end of the First World War (Nov 1st 1918) in Preseau, France where he was buried. Benjamin married his Cousin Madge, daughter of Alfred Colin Harse.

2/6. George William Harse (1865-1944), Son of Benjamin and Ann Adams

George married Lavinia Phipps from St Ebbes, Oxford.

The 1895-6 Walters Directory has William (George9) 1iving at 7 Cross Street

In 1910 Kelly’s Directory George is living at 110 Magdalen Road but by 1915 the Directory has George living at Mountain Ash Villa,127 Magdalen Road. George and Lavinia lived here until their deaths in 1944 and 1956 During the last few years of her life she had to share with the property owners a Mr and Mrs Cooper.

3/1. George Harold Harse (1892-?), Son of George and Lavinia Phipps

The 1926 Kelly’s Directory has George Harold living at 78 Divinity Road.

3/2. Ernest Percy (1894-1918), Son of George and Lavinia Phipps

Married ?

3/3. Lavinia Cissy Harse (1896-?). Daughter of George and Lavinia Phipps

Lavinia (or Cissy) married William Moss

They lived at 70 Bayswater Road, Barton, Headington.

3/4. Doris Harse (1899-1991), Daughter of George and Lavinia Phipps

Doris married Carl Hinrick Kampes from London

Doris and Carl, together with daughter Beryl_ and her sister Phyllis, emigrated to America in February 1929. They sailed from Southampton to New York then took a train to the Pasadena area of California.

3/5. Cyril William Harse (1901-), Son of George and Lavinia Phipps

Cyril married Doris Bice

3/6. Gladys Phyllis Harse (1904-1999) Daughter of George and Lavinia Phipps

Gladys Phyllis married Paul Terranova from America.

Gladys Phyllis and her sister Doris emigrated to America in February 1929.

3/7. Norman Stanley Harse (1910-1999) Son of George and Lavinia Phipps

Married Ivy Mabel Wharf from Bermondsey, London.

Norman served apprenticeships as both a Welder and a Ladies Hairdresser. Before the war he was working in London as a ladies hairdresser. Unfortunately his business went under. During the war, having a reserved occupation, he worked as a welder at the Pressed Steel factory in Cowley, Oxford. After the war Norman and his older brother George Harold set up in business as Cricket Ball Makers under the old name of Harse Brothers at the rear of New Inn Yard St Aldates. When Harold moved to Scotland Norman continued the business for a while but was eventually forced to close. Thereafter Norman become a taxi driver with Citax then became a proprietor himself.

He owned several licenses, some in partnership with Douglas McDonald who had worked for him making cricket balls, becoming a Director of Radiotaxis (Oxford) Ltd and was also part owner of the offices at la Warwick Street, Oxford.

They lived at 1 Henley Street, Oxford and by 1952 were living at 15 Temple Street, Oxford which they had purchased. They moved to 35 Spencer Avenue, Yarnton in 1961 where they lived until their respective deaths in 1989 and 1999

3/8. Lionel Dennis Harse (1914-1943). Son of George and Lavinia Phipps

Nothing is known about Dennis

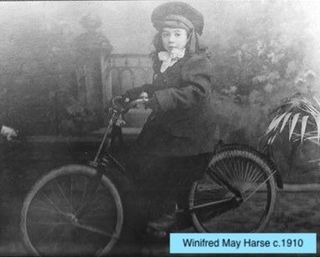

3/9. Walter Colin Harse (1890-1960), Son of Alfred Colin and Alice Moulder

Walter married Rosie Oxley.

The 1921 Kelly’s Directory has Walter living at 1 Richmond Road. Walter and Rosie lived here until there respective deaths in 1960 and 1979.

Son Walter left Oxford in 1927 to take up an Apprenticeship at Crewe with Rolls Royce He moved to London in 1932.

See also Harse, Ivor, An Oxford Childhood page

3/10. Morton G.W.B Harse (1889-?), Son of Morton Philip and Alexandra.

The 1949 Kelly’s Directory has Morton living at 64 Juxon Street where he remained until at least 1964.

4/1. David John Harse (1944-), Son of Norman and Ivy Wharf

David married Valerie Gurney from Oxford. There were further marriages to Jane Kerr and Elizabeth Kerr from Wallasey, Wirral.

He lived in the villages of Bletchingdon, (1969-1983), Kidlington (1983-1996), Cassington (1996-1999), before moving back to the family house in the village of Yarnton following the death of his father. Moved on to 36 Greenleas Road, Wallasey, Wirral in March 2001.

4/2. Richard George Harse (1948-). Son of Norman and Ivy Wharf

Richard married Laura Ledezma from Mexico.

Richard and Laura had two children. Eric and Stephanie